PAUL HAY Capital Projects

Pipe Size Calculation

Author: Paul Hay

e-mail: paul.hay@phcjam.com

profile: www.linkedin.com/in/phcjam

Problem:- Find service pipe size given the following:

Street main pressure [E] = 350 kPa

Height of uppermost fixture

(above street) = 10 m

Uppermost fixture = WC with flush valve

Total fixture units in the systema = 85

Total fixture units in the systema = 85

a. See table 1 for supply fixture units of individual plumbing fixtures.

Developed length (DL) of piping (to

highest and most remote fixture) = 30 m

Predominant flushing mechanism = Flush valves

Solution:- Calculation of Service Pipe Size

1. Find the pressure required in the system to provide the minimum fixture pressure [A] for uppermost fixtureb:

A = 103 kPa

Table 2: Minimum Pressure & Flow required for typical plumbing fixtures [source:- Mechanical & Electrical Equipment in Buildings]

2. Calculate the Static Head [B]:

B = 10 kPa/m x Height of uppermost fixture

= 10 x 10 m

= 100 kPa

Table 3: Minimum pipe sizes for typical plumbing fixtures [Source:- National Building Code of Jamaica 1983]

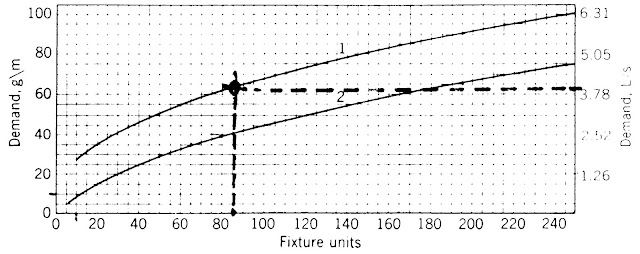

Figure 1: Demand Load for predominant (1) flush valves & (2) flush tanks [source:- Mechanical & Electrical Equipment in Buildings]

3. Using total fixture units, determine the demand loadc for the relevant flushing mechanism from figure 1.

5. Using demand load [3] and approx. pipe size [4], determine the pressure loss in the water meter [D] from fig. 3:

D = 62 kPa

6. Calculate the maximum frictional loss [C] that can be tolerated in the service pipe:

C = E - (A + B+ D)

= 350 - (103 + 100 + 62) = 350 - 265

= 85 kPa

7. Calculate the Pipe length equivalent of fittings

[DL'] (estimated at 20 % of DL):

DL' = 0.2 x DL = 6 m

8. Calculate the total equivalent length (TEL) of the piping:

TEL = DL + DL' = 30 + 6 = 36 m

9. Calculate the unit-frictional loss of the pipe:

100 x C/TEL = 100 x 85/36 = 189 kPa

e. 50 mm dia. service pipe size